Showa Denko Materials’ Low Transmission Loss Printed Wiring Board Material “MCL-LW-900G/910G” Adopted for the Printed Wiring Boards of the World’s No. 1[*1] Supercomputer, “Fugaku”

-

Showa Denko Materials’ Low Transmission Loss Printed Wiring Board Material “MCL-LW-900G/910G” Adopted for the Printed Wiring Boards of the World’s No. 1[*1] Supercomputer, “Fugaku”

-

Showa Denko Materials’ Low Transmission Loss Printed Wiring Board Material “MCL-LW-900G/910G” Adopted for the Printed Wiring Boards of the World’s No. 1[*1] Supercomputer, “Fugaku”

-

Showa Denko Materials’ Low Transmission Loss Printed Wiring Board Material “MCL-LW-900G/910G” Adopted for the Printed Wiring Boards of the World’s No. 1[*1] Supercomputer, “Fugaku”

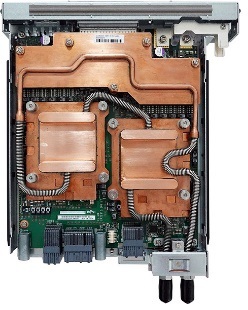

TOKYO--(Business Wire / Korea Newswire)--Showa Denko Materials Co., Ltd. (former Hitachi Chemical Co., Ltd.) (President and CEO: Hisashi Maruyama; hereinafter “Showa Denko Materials”) is pleased to announce that “MCL-LW-900G/910G,” a low transmission loss printed wiring board material developed by the company, has been adopted for the printed wiring boards mounted on the central processing units (CPU) of the supercomputer “Fugaku,” currently under joint development by the RIKEN and Fujitsu Limited.

The world’s No.1 supercomputer known as “Fugaku” aims to deliver up to 100 times the application execution performance of its predecessor, “K computer” that began operating in 2012, while minimizing its power consumption (30-40 MW) roughly three times that of “K computer” (12.7 MW). “Fugaku” is expected to play a major role in various fields, including COVID-19 research, artificial intelligence (AI) applications, and big data analysis.

To combine superlative computing speed and power-saving performance of “Fugaku,” higher speed communication, larger data volumes, and higher frequency electric signals are required for printed wiring boards. However, to provide these capabilities, it is essential to reduce transmission signal attenuation (transmission loss) and signal delay within the boards. Halogen-free material is also an important requirement to reduce environmental impact.

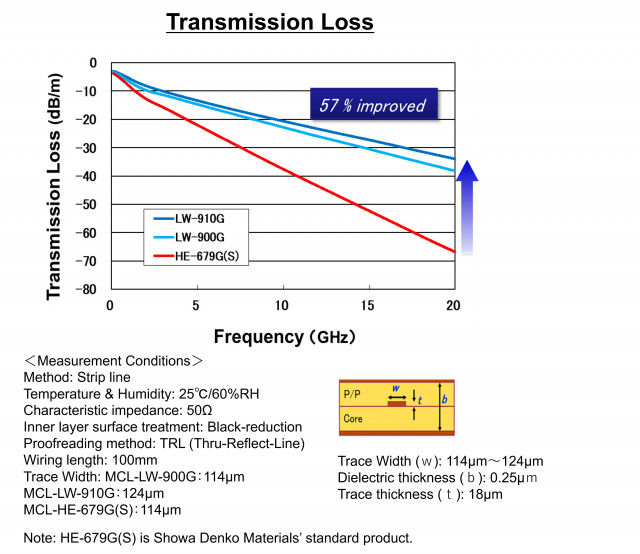

Showa Denko Materials developed “MCL-LW-900G/910G” as a halogen-free printed wiring board material capable of reducing transmission loss and signal delay by optimizing resin composition ratio and applying low dielectric[*2] glass cloth. This material is excellent for drilling holes and is applicable to laser drilling fine holes. It also effectively reduces the price of high layer count printed wiring boards as the material can be laminated collectively in a hybrid configuration with halogen-free FR4 (a general-purpose glass cloth base material) with different glass transition temperatures (Tg).[*3]

As a material for the supercomputer “Fugaku,” “MCL-LW-900G/910G” has been well-received for its properties such as low dielectric constant[*4] (Dk) and dielectric loss tangent[*5] (Df) related to transmission loss and signal delay, as well as insulation reliability[*6] (CAF resistance) and desmear treatment[*7] (desmear solubility) which improve printed wiring board production yields and ensure stable production.

Showa Denko Materials will work to further optimize the resin composition ratios and use lower dielectric glass cloth to launch mass production of printed wiring board materials focused on low transmission loss with a view to applying these materials to fifth-generation (5G) and sixth-generation (6G) mobile communication systems providing even higher speed, higher capacity, lower latency, and multiple connections.

[About MCL-LW-900G/910G]

Overview

MCL-LW-900G/910G is a multilayer printed wiring board material with a low dielectric constant and excellent thermosetting properties using glass cloth as its base material.

Features

· MCL-LW-910G achieved a dielectric constant of 3.3 and a dielectric loss tangent of 0.0028 (10 GHz) by combining low dielectric constant glass cloth and HVLP copper foil (low-roughness copper foil).

· It enables high-speed transmission/communication of 25 Gbps (gigabit per second) due to its excellent low transmission loss properties.

· It possesses superior heat resistance and connection reliability.[*8]

General Properties (To view the table, please visit https://bwnews.pr/3dxzCZS)

*JPCA-TM001

Applications

High-speed computers, servers, high-speed routers, communications equipment, high-frequency components, high-frequency radars/antennas

For inquiries, please use the contact form at the following URL.

https://www.mc.showadenko.com/english/products/bm/index.html

[*1] The supercomputer Fugaku topped the world supercomputer rankings announced in June 2020, claiming the top spot in four categories: the TOP500 list based on the LINPACK (computer performance measurement program) benchmark measuring the execution performance; HPCG (High Performance Conjugate Gradient), measuring the solving performance of simultaneous linear equations by the Conjugate Gradient (CG method); HPL-AI, measuring the computing performance of artificial intelligence (AI) applications; and Graph500, measuring the performance of data-intensive applications, including big data analysis.

[*2] Low dielectric refers to the propagation of electric signals speeding up with a lower dielectric constant.

[*3] Glass transition temperature (Tg) refers to the temperature where a polymer substance changes from a rigid glassy material to a rubbery material.

[*4] Dielectric constant refers to the value representing the degree of electronic polarization of a substance in an electric field that exerts force on a charged object, expressed as the ratio of the permittivity of vacuum.

[*5] Dielectric loss tangent refers to the degree of energy loss in a substance, which enables to evaluate transmission loss and signal delay.

[*6] Insulation reliability refers to the reliability of electric insulation between wires and layers.

[*7] Desmear treatment refers to removing resin smears formed on the inner wall of holes during the drilling process of blind vias through-holes by laser drilling to prevent such defects as poor interlayer conductivity and delamination.

[*8] Connection reliability refers to the reliability of electric connections between layers and between semiconductor chips and boards.

Photos/Multimedia Gallery Available: https://www.businesswire.com/news/home/52303539/en

Website: https://www.mc.showadenko.com/english/

View Korean version of this release

Contact

Showa Denko Materials (America), Inc.

Dragon Hikida

+1(408)507-9058

This is a news release distributed by Korea Newswire on behalf of this company.